Valves

A valve is a device used to regulate the flow of fluids in a pipe or enclosure.

Know more

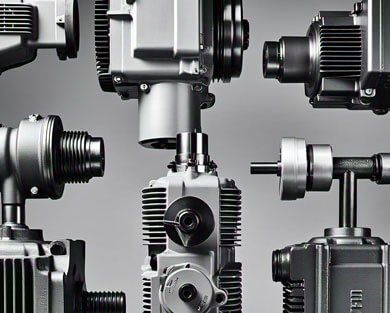

A motor is a device that converts electrical energy into mechanical energy, typically rotational motion. This conversion is achieved through the interaction of magnetic fields and electric currents. Electric motors are the backbone of many industries, driving everything from machinery to transportation.

Your Global Source for Reliable Industrial Motor

Induction Motors: These are the most widely used type of industrial motor, known for their reliability and efficiency. They work on the principle of electromagnetic induction.

Synchronous Motors: These motors operate at a constant speed, synchronized with the frequency of the supply current. They're often used in applications requiring precise speed control.

DC Motors: Direct Current motors are used in applications where speed control is crucial. They offer high starting torque and are easy to control.

Stepper Motors: These motors move in discrete steps, making them ideal for applications requiring precise positioning and control, such as CNC machines and robotics.

Servo Motors: Servo motors are used in applications requiring precise control of position, velocity, and torque. They're commonly used in robotics, CNC machines, and other precision applications.

Brushless DC Motors: These motors offer high efficiency, reliability, and longevity, making them suitable for applications like robotics, medical devices, and industrial automation.

Single-Phase Motors: These motors are used in smaller applications, such as household appliances and small industrial equipment.

Three-Phase Motors: These motors are commonly used in industrial applications, offering higher power and efficiency compared to single-phase motors.

High Efficiency: Modern motors are designed to optimize energy efficiency, reducing energy consumption and costs.

Precise Control: Advanced motor control systems enable precise speed, position, and torque control, improving overall system performance.

Reliability: Motors are built to withstand harsh industrial environments, ensuring reliable operation and minimizing downtime.

Compact Design/ Flexibility: Many motors are designed to be compact and lightweight, making them ideal for applications where space is limited.Motors come in a range of sizes, types, and configurations, making the

Increased Productivity/ Energy Savings: Motors enable automation, improving production efficiency and reducing labor costs.High-efficiency motors reduce energy consumption, lowering operating costs and minimizing environmental impact.

Improved Accuracy: Precise motor control enables accurate positioning, speed, and torque, improving overall system performance.

Reduced Maintenance/ Enhanced Safety: Reliable motor operation and advanced control systems minimize downtime and reduce maintenance needs.Motors can be designed with safety features, such as overload protection, to ensure safe operation and protect personnel.

Power Rating - 1-1000 kW (1-1341 HP)

Voltage - 230/400/690V, 3-phase

Frequency - 50/60 Hz

Speed - 1000-3600 rpm

Efficiency - IE1-IE4 (Standard to Super Premium)

Insulation Class -F, H, or higher

Protection Class - IP55, IP65, or higher

Mounting Type - Foot-mounted, flange-mounted, or face-mounted

Cooling Method -Self-cooling, forced cooling, or water cooling

A valve is a device used to regulate the flow of fluids in a pipe or enclosure.

Know more

A pump transports liquids or gases by generating a pressure differential.

Know more

A gasket creates a pressure-tight seal between components by filling the space between them.

Know more

Fasteners are hardware components used to join or affix two or more objects together.

Know more

Gearboxes use gears to transfer power and modify speed or torque in mechanical systems.

Know more