Valves

A valve is a device used to regulate the flow of fluids in a pipe or enclosure.

Know more

A gasket is a mechanical seal that fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. Gaskets allow for “less-than-perfect” mating surfaces on machine parts where they can fill irregularities.

Spiral Wound Gaskets: Made from a spiral wound metal strip with a filler material, these gaskets are suitable for high-temperature and high-pressure applications.

Sheet Gaskets: Cut from a sheet of material, these gaskets are commonly used for low-pressure applications and are available in various materials like rubber, cork, and graphite.

Metal-to-Metal Gaskets: These gaskets are designed for high-pressure and high-temperature applications, where metal-to-metal contact is required.

Rubber Gaskets: Made from rubber or elastomeric materials, these gaskets are suitable for applications where flexibility and sealing are required.

Spiral Wound Graphite Gaskets: These gaskets combine the benefits of spiral wound gaskets with the properties of graphite, making them suitable for high-temperature applications.

Kwik-Flange Gaskets: These gaskets are designed for ease of installation and removal, making them suitable for applications where frequent maintenance is required.

RTJ (Ring Type Joint) Gaskets: These gaskets are designed for use in high-pressure applications, such as oil and gas, and are made from metal.

Soft Sheet Gaskets: These gaskets are made from soft materials like rubber, cork, or paper, and are suitable for low-pressure applications.

Metal Jacketed Gaskets: These gaskets have a metal jacket surrounding a soft filler material, making them suitable for high-temperature and high-pressure applications.

Corrugated Gaskets: These gaskets have a corrugated design, which provides a high level of sealing performance and flexibility.

Sealing Performance: Gaskets provide a reliable seal between two mating surfaces, preventing leakage and contamination.

Flexibility: Many gaskets are designed to be flexible, allowing them to accommodate slight movements and vibrations.

Chemical Resistance: Gaskets can be made from materials that resist chemical attack, ensuring long-term performance.

Temperature/ Pressure Resistance: Gaskets can be designed to withstand a wide range of temperatures, from extreme cold to high heat. Gaskets can be designed to withstand various pressure ranges, ensuring reliable performance.

Prevents Leakage/ Reduces Maintenance: Gaskets prevent fluids, gases, or other substances from escaping or entering a system.By providing a reliable seal, gaskets can reduce the need for frequent maintenance and repairs.

Increases Safety: Gaskets can help prevent accidents and injuries by ensuring that systems operate safely and efficiently.

Improves Efficiency/ Extends Equipment Life: By preventing leakage and contamination, gaskets can help improve the overall efficiency of a system.By providing a reliable seal, gaskets can help extend the life of equipment and reduce downtime.

A valve is a device used to regulate the flow of fluids in a pipe or enclosure.

Know more

A pump transports liquids or gases by generating a pressure differential.

Know more

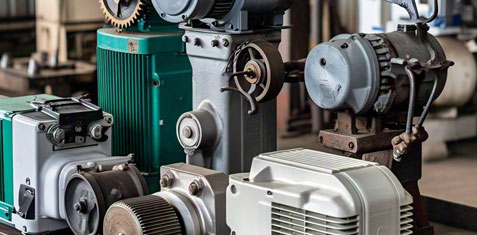

A motor is a device that converts electrical energy into mechanical energy, typically rotational motion.

Know more

Fasteners are hardware components used to join or affix two or more objects together.

Know more

Gearboxes use gears to transfer power and modify speed or torque in mechanical systems.

Know more